I can provide some additional context here.

Hello again everyone, let’s see if I can remember how this forum works.

WotC designs cards and does the prepress work.

WotC hires a print facility to manufacture the physical cards.

The print facility is in the business of printing things, and they purchase various supplies from other companies.

The ink comes from another company.

The sheets of unprinted cardstock come from another company.

The booster wrappers (which are called “flow wrap”) come from another company.

Originally, all the WotC booster wrappers were supplied by a company named Spruyt in Belgium, but that company went out of business at the end of 1994, so they weren’t used for Pokémon.

After Spruyt, all WotC booster wrappers were supplied by a company named Vitra.

Vitra is still supplying WotC with booster wrappers today, though it’s possible WotC could have additional suppliers now.

Booster wrappers are made by the Vitra Creavit team.

Vitra was purchased by Korozo near the end of 2019, and the company name changed slightly to VitraPack.

I think booster wrappers are made on a web press using long continuous rolls of material, instead of a sheet fed press like the cards.

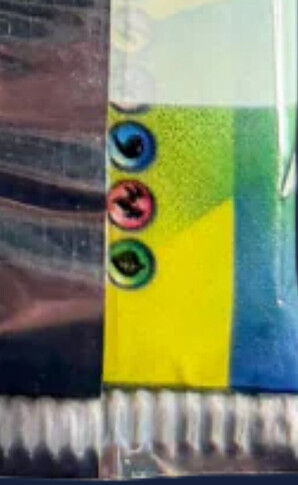

Here’s a picture of Magic The Gathering 4th Edition booster wrappers from 1995, to help you understand.

Pokémon booster wrappers were made the same way.

(hmm, how do I add a picture… ah, I think it’s this button.)

In that picture, you can see the same artwork across each row, with different rows having different artwork.

Magic The Gathering 4th Edition had 5 different artworks for booster wrappers, so the art repeats after 5 rows.

It would be MUCH longer than what’s shown here. This is just a small piece.

This picture is 5 packs wide, but in later years they were able to make it wider in order to print more booster wrappers in the same time.

After printing it like this, it goes through a slitter to separate it into rolls that are only 1 pack wide with alternating artwork.

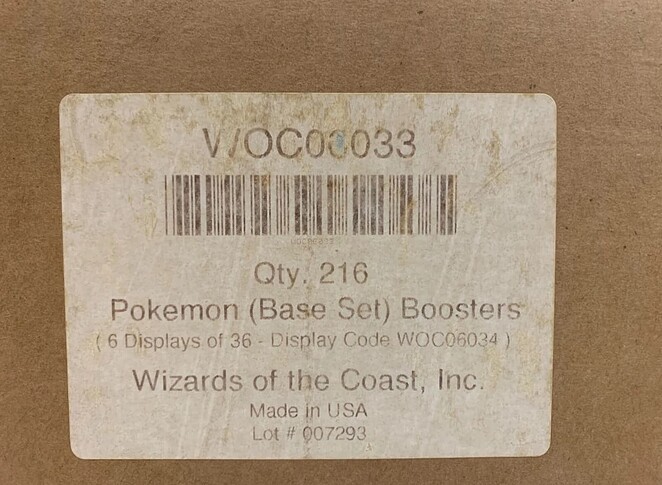

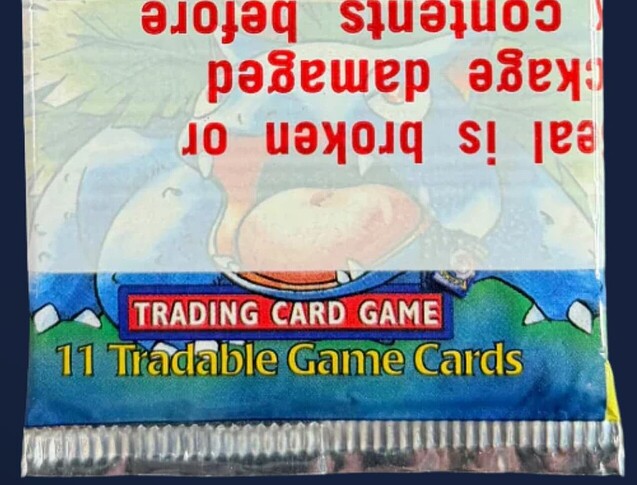

Here’s an example showing Magic The Gathering Visions & Weatherlight booster wrappers from 1997.

Visions & Weatherlight had the same artwork on every pack, so you won’t see alternating art here.

Again, this is just a small sample. The length of material is quite long on each roll, so that it doesn’t have to be replaced as frequently during use.

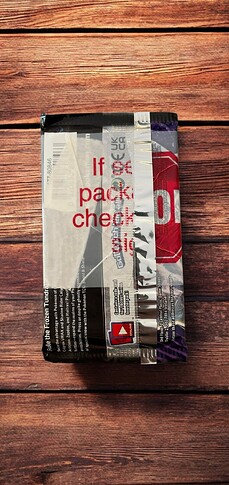

I’ve seen the red tape quite a few times on Magic The Gathering booster packs, and I’ve heard that it’s applied near the end of each roll to signal to the machine operator that the roll of booster wrapper material will need changed soon.

I’ve also seen black tape.

This is applied during manufacturing of the booster wrapper material, not at the TCG print facility.

Some of the Pokémon examples above, show the printing “on top of” the red tape.

The facility that creates the booster wrappers, wouldn’t have much need for Stop Tape as far as I know, because it’s a large wholesale transaction between industry partners, and shipped on a pallet, not inside little retail cardboard cases.

The booster material itself starts as a clear plastic.

The booster image is printed on the inside of the clear plastic, like Picasso painting on a glass window.

In this picture, I’m holding a roll of this clear booster material that’s been printed with the booster image for German Magic The Gathering Portal from 1997.

The next step after this, is to apply the shiny reflective silver (or gold) coating that you see inside the booster wrappers.

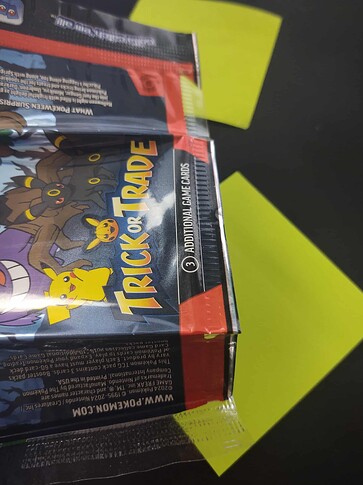

To show you that this info applies to Pokémon, and is still applicable today, here’s a couple pictures of a Pokemon Trick or Trade 2024 wrapper (not a WotC product), which I opened a few days ago on Halloween 2025.

This clearly shows the clear plastic material, with printing inside, which is covered by a silver coating.

On the crimp area, you can see that the printed ink stayed stuck to the silver coating, while the clear plastic peeled away.

It was a pretty good opening. I got the most expensive card in the set, if anybody wants to watch.

https://youtu.be/jau9BT2Lbtw?si=C6hHTJRBCV-1YY9x

I haven’t seen the Stop Tape on a booster pack before, but maybe it could happen at the TCG print facility (or Pack Out Facility) while they’re switching from an empty roll of booster wrappers to a new roll, or if a roll breaks in the middle and they have to patch it together to use the rest of the roll.

If you were patching two pieces of material together, you’d overlap it to the correct pack dimension, and tape it.

The facility which is packaging the cards into boosters and putting them into boxes and cases, would have Stop Tape handy.

Tavis King